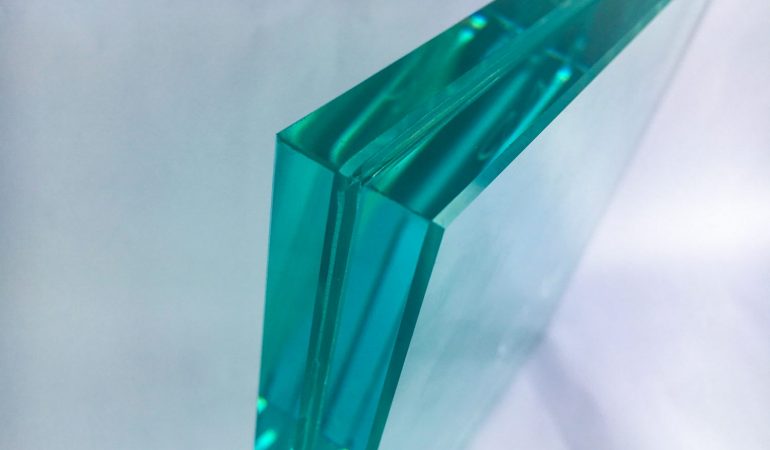

Laminated glass is the process of joining two flat or colored glasses under pressure with a substance called PVB.

The lamination process combines two glasses with high pressure, preventing the glass from dispersing at the time of breaking and falling pieces. So it is important for security. According to the new laws, it is mandatory to use laminated glass in the handrail glasses used in the buildings. It is also used in showcases, facades, balconies and many other areas as it provides high strength to glass. Laminated glass, which is getting more and more space every day, is exposed to many wrong applications due to wrong technique and information.

Different PVBs and different glass processes should be applied according to the desired properties in laminated glasses.

For example, acoustic laminated glass prevents disturbance from sound and noise with PVB that insulates sound. Acoustic laminated façade and double glazing provide serious comfort in noisy environments.

When color is desired, ambient color can be obtained with colored PVBs. Possible injuries can be avoided by using fully tempered, semi-tempered and non-tempered glasses together on glass floors.

What thickness of PVB should be used? What thickness should the glasses be? Should they be tempered? Such questions vary according to the area to be used and technical calculations.

A common problem with laminated glass is stains on laminated glass called speckles. These stains are caused by mistakes made in temper temperature or quench period and with small curvature on the glass. In the lamination process, when the curved parts are not fed with sufficient PVB, spot discoloration can be seen. Correct materials and workmanship are required to avoid these mistakes.