Tempering is the most vital stage of the glass processing department. Most of the faults you see on glasses are caused by the faulty tempering process.

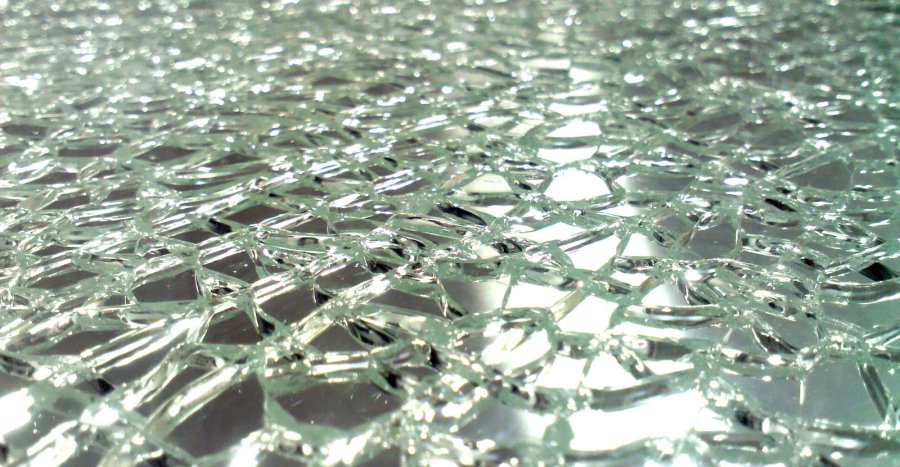

Temper process is the process of raising the glass to a certain degree according to its type and then cooling it quickly. This process creates a tension – tensile force area in the glass and in case of an impact, it prevents injuries by breaking into small pieces.

Unfortunately, the tempering process is not Unfortunately, the tempering process is not equal by purchasing only a temper machine. An enormous technical knowledge and experience is required. Different temperatures should be applied according to the shape, thickness, coating, color and size of the glass. How long the glass will remain in the heat treatment depends on the type of glass and many properties. Likewise, the cooling of the glass, the proximity of the cooling turbines, the cooling time and hundreds of other factors change the tempering properties of the glass. Unfortunately, as a result of the unconscious tempering process, roller marks on the glass, rainbow color formations, lensing, curvature on the glass, bad appearance of the glass in buildings, fluctuation and many other bad results may occur. In addition, not being cut into pieces of the desired number and size can still cause dangerous results.

Our company has great technical experience and knowledge in the field of temper for years with 2 temper machines with convectional equal heat distribution. We are pleased to assist you in all areas. Our tempering process is carried out according to TS EN 12150-1 standards.

Although the tempering process gives the glass a certain resistance to impacts and temperature changes, this is not the purpose of temper. Because the resistance of the glass, which increases in strength from the edges, decreases against impacts from the corners. The aim is to cut it into small non-hazardous pieces in case of disintegration.

In addition, a subject that is misunderstood is the issue of semi-temper. Some product can be semi-tempered according to its shape or area of use. This is not a method of deception. Users who want the parts not to fall apart should prefer the lamination process in addition to the tempering process.